Electric Mid&Hi Fired Ceramics

Potters & Sculptors - Making Rock from Mud

I know I can't Soda fire in my electric kiln (without ruining it) but is there a simple way to fake a Soda glaze?

I plan to test a couple of ideas but wondered if anyone had beat me to it.

First idea is to make a saturated solution of Sodium Carbonate and either spray/dip/paint it on a bisqued piece and just fire it (on a catch plate).

I'll try a second pot with a (hopefully) complimentary glaze on it as well, and maybe a third with the Soda sprayed on afterwards.

Tags:

Replies to This Discussion

-

Permalink Reply by Norm Stuart on November 13, 2016 at 2:34pm

-

Ayjay -- Soda Ash anhydrous Na2CO3 or light Na2CO3·H2O (or Salt) can create a surface layer of Sodium Silicate on a clay body. "Heavy Soda Ash" decahydrate is fully hydrated Na2CO3·H2O and difficult to work with.

Na2CO3·H2O + SiO2 = Na2SiO3 + CO2 + O2 + H2O

While Sodium Carbonate decomposes into Sodium Oxide and Carbon Dioxide around Cone 012, it doesn't generate any vapor until Cone 9 or so with Cone 12 being more effective. So the traditional method of simply dumping soda into a kiln doesn't work at Cone 6 and is not a nice thing to do to a kiln anyway.

As you suggest applying the Soda to the clay as a glaze is the way to go

I dip bisqued Cone 10 paper clay into a solution of half sodium carbonate and half lithium carbonate which densifies the otherwise porous clay when fired only to Cone 6. I balance the Sodium with Lithium to try to maintain the thermal expansion of the clay. After it's dry I can also glaze the piece - with the water soluble fluxes providing some additional movement between glaze and clay.

But there's no melted "salt look" of Sodium Silicate on the surface of this Cone 10 paper clay surface at Cone 6.

Sodium Oxide needs additional fluxes to create a glass-like surface on clay at Cone 6. The most common low temperature flux is Boron, but many add Calcium which becomes a flux at Cone 6. This is one of the links to Digitialfire

https://digitalfire.com/4sight/oxide/na2o.html

Here's 3 different ways to achieve some sort of "salt fire" look.

"Soda Glaze" Solution #1

50% Sodium Carbonate - substitute Sodium Bicarbonate for half of this to make a less alkaline solution

50% Calcium Carbonate

"Soda Glaze" Solution #2

80% Kaolin

10% Nepheline Syentite

10% Silica

Nepheline Syenite melts at Cone 02, but a small percentage of boron from Ferro Frit may be needed to achieve the look you're looking for.

https://digitalfire.com/4sight/material/nepheline_syenite_1069.html

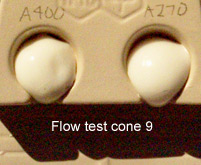

As you can see Nepheline Syenite by itself doesn't flow much even at Cone 9.

"Soda Glaze" Solution #3

50% Sodium Carbonate

50% Boric Acid

Boric acid forms a glass which is similar in look, but is not Sodium Silicate.

Try these out and post some photos!

.

-

Permalink Reply by Ayjay on November 14, 2016 at 10:14am

-

Thanks for the comprehensive reply Norm, there's a lot to think about there.

I thought I already had a few ideas too many and now I have several more.

I'll definitely try some of those, in conjunction with some other ideas as well.

If I can get somewhere close to the mug below I'll be a happy bunny.

- Attachments:

-

-

soda_mug.jpg, 511 KB

soda_mug.jpg, 511 KB

-

-

Permalink Reply by Tom Anderson on November 17, 2016 at 8:04am

-

Norm:

Have you ever experimented with using Minex 400 in lieu of 270? Particle/mesh size does play a role in melt. An example: regular silica melts at 3150 +/-, and Imsil A25 melts at 2950 +/-. Just the difference in mesh/micron sizes lowers melt temps.

Tom

-

Permalink Reply by Norm Stuart on November 17, 2016 at 5:45pm

-

I try to purchase fine materials, but no finer than 350 mesh to avoid aerosolized dust. 400 mesh is nearly the same size but 350 is my cut-off.

With the material we purchase you'd be surprised how many glazes containing frit are just as melted at Cone 2 as they are at Cone 6.

Coarse material can in theory develop a minuscule percentage of small aerosolizeable particles as it's banged about being transferred into bags. But I merely don't want a studio where everyone doesn't have to wear respirators.

-

Permalink Reply by Tom Anderson on November 17, 2016 at 8:20pm

-

That is certainly a justifiable and good reason to purchase 350 mesh. However, Imsil A25 is an agglomerate material: meaning it clumps together by static forces: and emits almost zero dust as compared to regular silica. Sorta like powdered sugar compared to flour in regards to dust. Once it hits water though, it disperses almost without stirring, BUT- I certainly commend you on studio safety.

Tom

-

Permalink Reply by Norm Stuart on November 17, 2016 at 8:57pm

-

I've used A-25 Silica and it readily aerosolizes rigtht before your eyes.

Slowly draw a circle in the silica powder in a bag of A-25 with your finger or chopstick and the cloud will slowly rise and then pour over the low side of the bag of A-25 Silica and run across the dining room table where I was using it. When I came back I could see the white plume of dust left on the mahogany table and where it poured off the side of the table.

You can minimize this behavior by keeping the fine material at a high level of humidity, but it still happens. Our studio is outdoors and often windy - so even 350 mesh takes flight but it's weighted enough that it's headed toward the ground.

Remember, the danger of aeresolized silica is the silica in the air you can't see. Because it has so much surface area relative to its weight, the A-25 silica particles readily penetrate past your sinuses and trachea down into your lungs where they remain. Someone accidentially bought a 50 pound bag of A-25 and after explaining why they had to toss it, I carefully opened the bag and gave it a little stir - and they were convinced.

The spreadsheet in the prior post comparing risk with particle size is taped to the inside of one of our material cabinets.

Uneducated people can often come to see ceramic materials as being dangerous in a "radioactive" manner where they're dangerous to be close to, rather than certain of the items you don't want to eat, or fine materials you don't want to breath.

I saw someone ask a ceramic teacher if they should wear latex gloves when they throw on the wheel because commercially prepared clay contains barium to prevent scumming.- he said "No, you just need to minimize the quantity of clay you eat each day. Oh, the look on their face!

-

Permalink Reply by Ayjay on January 2, 2017 at 2:37pm

-

Well, none of my first tests (four small beakers with a different concoction on each side) produced anything I want to repeat.

There was however a happy accident in the same firing, I glazed this pot with a mixture of Richard Busch's Nutmeg and White Satin Matt and then sort of stippled another white (Behren's Pearly White) over the top with a silicon pastry brush.

I'm quite pleased with the effect and will play with it some more.

- Attachments:

-

-

bottle_nutmeg_sodaQ.jpg, 328 KB

bottle_nutmeg_sodaQ.jpg, 328 KB

-

-

Permalink Reply by Norm Stuart on January 2, 2017 at 4:01pm

-

That's a really nice result. Trial and error layering glazes can produce phenomenal results along with a bunch of dreck.

Calcium Carbonate and Sodium Carbonate decompose into CaO and Na2O by Cone 012, so they're certainly an active flux on the surface of the ware at Cone 6.

But the articles about (Soda Ash / Calcium Carbonate) used as a glaze for "soda firings" such as this one,

Calcium Carbonate / Sodium Carbonate Glaze

never specify the Cone temperature, so It may be the reaction of these fluxes with the clay body to create a "Soda Fire" look as shown below in the second photo requires more heat than Cone 6 supplies. Which merely means more flux is needed or mixing the flux with clay body as a slip.

This article also mentions the a "Soda Slip" made of Silica, Kaolin and 10% Nepheline Syenite and 5% Bentonite. Just a s guess, but I suspect the 5% Veegum/ Bentonite (magnesium and/or calcium) is an important part of the flux for this slip

.

A photo from the article ostensibly showing a bowl coated with Soda Ash / Calcium Carbonate and fired to an unspecified Cone, probably Cone 10. Or is it the "Soda Slip"? Spoilers.

Ayjay said:

Well, none of my first tests (four small beakers with a different concoction on each side) produced anything I want to repeat.

There was however a happy accident in the same firing, I glazed this pot with a mixture of Richard Busch's Nutmeg and White Satin Matt and then sort of stippled another white (Behren's Pearly White) over the top with a silicon pastry brush.

I'm quite pleased with the effect and will play with it some more.

Videos

Use These Links to Support Us

Low cost flat lapping disc can be used on you potters wheel if you, drill bat pin holes in it, and provide a trickle of water to cool it. At amazon.com, 120 grit for aggressive material removal. Click the image to purchase

Members have had great things to say about John Britt's new book, Mid-Range Glazes. Click the image to buy from Amazon.com

Purchase Glazes Cone 6 by Michael Bailey, The Potters Book of Glaze Recipes by Emmanuel Cooper, or Making Marks by Robin Hopper, all available at amazon.com. Mastering Cone 6 Glazes by John Hesselberth & Ron Roy is now out of print.

Harbor Freight is a great place to find unbeatable prices for better HVLP spray guns with stainless steel parts and serviceable economy models, as well as detail guns, all tested by our members for spraying glazes, as well as compressors to power the guns. As yet no one has tested and commented on the remarkably inexpensive air brushes at harbor freight.

The critter siphon gun is a spray alternative that is well liked by some of our members, and is available at amazon.

Amazon is also a competitive source for photo light tents for shooting professional quality pictures of your work. They also have the EZ Cube brand favored by several of our members. You might also want to purchase the book Photographing Arts, Crafts and Collectibles . . .

If you are up to creating videos of your work or techniques you might want to invest in a flip video camera

Following are a few scales useful for potters. Ohaus Triple Pro Mechanical Triple Beam Balance, 2610g x 0.1g, with Tare $169.00

And finally a low cost clone of the OHaus. The Adam Equipment TBB2610T Triple Beam Mechanical Balance With Tare Beam $99.62

ebay is a great alternative for many tools and the equipment used in the ceramics studio - kilns, wheels, extruders, slab rollers are often listed there both new and used.

Tips for Members

If you just want to spout off, it is best accomplished as a blog posting. If you want to get more guidance and ideas from other members, ask a question as a new discussion topic. In the upper right corner of the lists for both types of posting, you will find an "+Add " button. Clicking it will open an editor where you create your posting. 4/16/2014

© 2026 Created by Andrea Wolf.

Powered by

![]()