Electric Mid&Hi Fired Ceramics

Potters & Sculptors - Making Rock from Mud

Has anyone tried out Assad Black from John Britt's Mid-Range Glazes? There is a photo of one of Christa Assad's pieces on page 140 and the recipe is on page 138.

My question: is it possible there is something missing in the oxides such as cobalt or manganese or iron? Or is it possible that this recipe as it is printed with only copper carb will produce black?

I've mixed up a test amount but am thinking to divide it up and add additional oxides to some tests. But perhaps someone will tell me that there is a combo in this recipe that will produce black.

Tags:

Replies to This Discussion

-

Permalink Reply by George Lewter on May 29, 2015 at 3:02pm

-

John Britt is a member here (though not very active). Why don't you message him directly and avoid intermediaries?

-

Permalink Reply by Norm Stuart on May 30, 2015 at 12:50am

-

This is Digitalfire's commentary on Copper Oxide, which is a black matte powder.

http://digitalfire.com/4sight/material/copper_oxide_black_237.html

"One of the oldest colorants used by potters. It is a popular source of copper in glazes and glass. It is a very strong flux, in a mix of 50% Ferro borax frit 3134 it will dissolve a firebrick crucible at cone 6! It is the most stable form of oxidized copper (Cuprous oxide oxidizes to cupric oxide in normal firings).

The oxide form of copper can give a speckled color in glazes whereas the carbonate form will give a more uniform effect.

Copper normally produces green colors in amounts to 5% where it moves toward black in oxidation firing.In reduction firing, it turns to Cu2O and gives vibrant red hues. It the glaze is fluid copper will tend to crystallize heavily. See CuO and Cu2O in the oxides database for more information.

Above 1025C copper becomes increasingly volatile and its crystalline structure breaks down. At 1325C CuO melts. This can affect the color of other glazes pieces in the kiln. Glazes containing copper can change significantly because of loss of copper. Some potters alternate between reduction and oxidation, and even put a dish filled with copper carbonate in the center of the kiln to minimize this phenomenon.

There are many workable copper ores (i.e. tenorite, cuprite). Source: American Chemet Corp., 708-948-0800 FAX 708-948-0811

See also: "Coloring Mechanism of Peach Bloom Copper Red Glazes" written by four technicians from China published in Dec 91 Bulletin of the American Ceramic Society."I'd guess the color also depends on the glaze chemistry. But here's two test tiles, the first with 4% CuO the second 6% CuO.

This first test tile is 100% Ferro Frit 3269 mixed with 4% black copper oxide.

My second tile is the same 100% Ferro Frit 3269 with 6% black copper oxide. If you look close the dark, almost black glaze contains what looks like metallic copper crystals.

If you want to dissolve Black Copper Oxide for any reason, it's soluble in Ammonia.

Not having Britt's book I'd be interested in the recipe.

-

Permalink Reply by Gina Skillings on May 30, 2015 at 9:53am

-

Thanks George. I will fire the tests I have mixed up first.

George Lewter said:John Britt is a member here (though not very active). Why don't you message him directly and avoid intermediaries?

-

Permalink Reply by Gina Skillings on May 30, 2015 at 10:00am

-

Thanks Norm. The recipe calls for copper carbonate, not oxide. That is what surprises me.

Norm Stuart said:This is Digitalfire's commentary on Copper Oxide, which is a black matte powder.

http://digitalfire.com/4sight/material/copper_oxide_black_237.html

"One of the oldest colorants used by potters. It is a popular source of copper in glazes and glass. It is a very strong flux, in a mix of 50% Ferro borax frit 3134 it will dissolve a firebrick crucible at cone 6! It is the most stable form of oxidized copper (Cuprous oxide oxidizes to cupric oxide in normal firings).

The oxide form of copper can give a speckled color in glazes whereas the carbonate form will give a more uniform effect.

Copper normally produces green colors in amounts to 5% where it moves toward black in oxidation firing.In reduction firing, it turns to Cu2O and gives vibrant red hues. It the glaze is fluid copper will tend to crystallize heavily. See CuO and Cu2O in the oxides database for more information.

Above 1025C copper becomes increasingly volatile and its crystalline structure breaks down. At 1325C CuO melts. This can affect the color of other glazes pieces in the kiln. Glazes containing copper can change significantly because of loss of copper. Some potters alternate between reduction and oxidation, and even put a dish filled with copper carbonate in the center of the kiln to minimize this phenomenon.

There are many workable copper ores (i.e. tenorite, cuprite). Source: American Chemet Corp., 708-948-0800 FAX 708-948-0811

See also: "Coloring Mechanism of Peach Bloom Copper Red Glazes" written by four technicians from China published in Dec 91 Bulletin of the American Ceramic Society."I'd guess the color also depends on the glaze chemistry. But here's two test tiles, the first with 4% CuO the second 6% CuO.

This first test tile is 100% Ferro Frit 3269 mixed with 4% black copper oxide.

My second tile is the same 100% Ferro Frit 3269 with 6% black copper oxide. If you look close the dark, almost black glaze contains what looks like metallic copper crystals.

If you want to dissolve Black Copper Oxide for any reason, it's soluble in Ammonia.

Not having Britt's book I'd be interested in the recipe.

-

Permalink Reply by Norm Stuart on May 30, 2015 at 10:51am

-

Once the temperature rises to just 554 F (290 C) Copper Carbonate (Cu2 (OH)2 CO3) quickly breaks down into Black Copper Oxide (CuO), Carbon Dioxide (CO2), and steam (H2O). So they're interchangeable with a weight adjustment just like Cobalt Carbonate and Cobalt Oxide.

(Cu2 (OH)2 CO3) = 2 CuO + H2O + CO2

You can also purchase Red Copper Oxide which has to remain coated with oil to remain stable, otherwise it slowly oxidizes into Black Copper Oxide at room temperature. Even coated with oil Red Copper Oxide about half will be converted after 12 months, resulting in a brown color on it's eventual pathway to black.

Cu2O + O = 2 CuO

-

Permalink Reply by Gina Skillings on May 30, 2015 at 11:04am

-

Oh yes, thanks Norm. I had once known that but of course forgotten. I should know on Monday if the 4.2% of copper carb makes this black. It has some zinc which the combo can make purple so perhaps it will happen.

-

Permalink Reply by Gina Skillings on June 1, 2015 at 8:43am

-

I unloaded my tests this morning. Assad Black does indeed go black but I'm glad I added 10% RIO to one test as it produced the glaze I was hoping for. It may have a slightly different surface next time I fire it as this was my new kiln's first load and it went to cone 7. Black Assad as printed is on the test tile and the version with RIO is on the bell.

-

Permalink Reply by Norm Stuart on June 1, 2015 at 10:07am

-

The glaze with the added iron oxide is very nice. What percentage copper carbonate does it contain?

Congratulations.

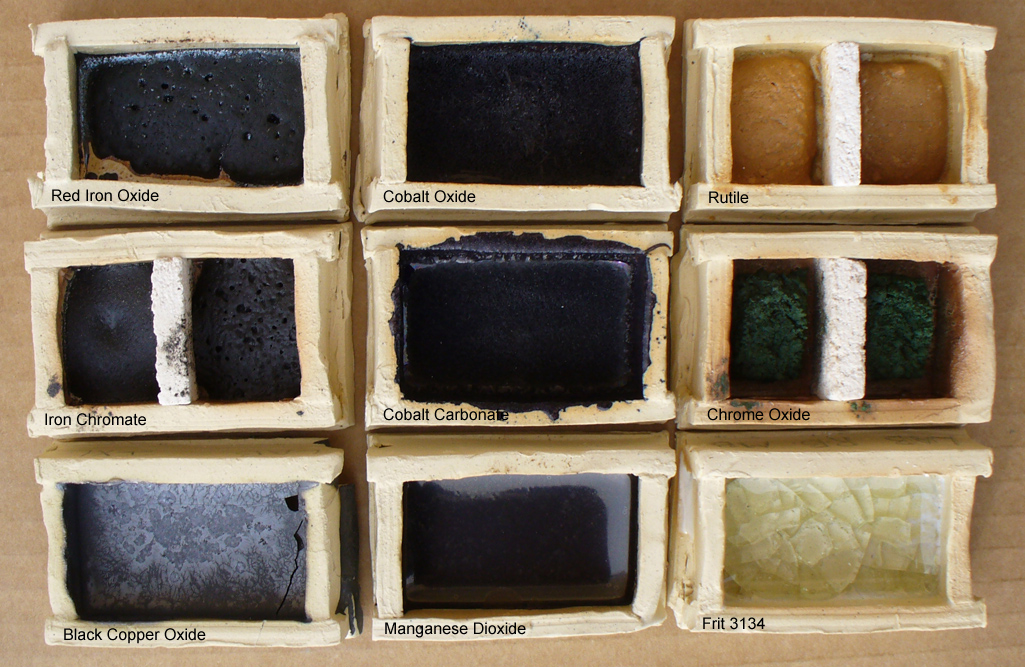

I think this an interesting photo from Digitalfire. 50% Ferro Frit 3134 with 50% of various oxides.

If you didn't know that copper is the most easily leeched colorant, which can make otherwise stable glazes unstable, you could probably guess that from looking at the crystalline structure on the surface of the 50% Black Copper Oxide with 50% Ferro Frit 3134.

xxxxxxxxxxxxxxxxxxxxxxxx

I'm applying a black and white "underglaze" to a piece I hope will be look very dry. I'm using two very refractory colors.

95% Iron Chromate with 5% Cobalt Oxide for the black

100% Titanium Dioxide for the white.

Both are mixed with bentonite and two fluxes.

1.) Potassium Carbonate

2.) Lithium Carbonate

Of course my black surface will not be food safe.

Effectively the surface of the clay will become an important component of the glaze, as with this recipes for a metallic gold.

20.0% Red Art Clay 60.0% Manganese Dioxide 10.0% Grolleg Kaolin aka China Clay 10.0% Copper Oxide or 13.9% Copper Carbonate

-

Permalink Reply by Gina Skillings on June 1, 2015 at 10:16am

-

It has 4.2 copper carb

I also slow cooled at 100% per hour from top temp to 1400

-

Permalink Reply by Gina Skillings on June 1, 2015 at 10:52am

-

The metallic gold recipe you mentioned may be similar to one in the studio where I teach. I'm hoping to end it's use eventually because of the manganese as our kilns are right in the studio and I have ventilation concerns.

Are you applying your 'underglazes' before bisque? I just ran a test of a glaze I made up several years ago that at the time was very dry but this time it was quite satin. Perhaps glazes materials, temperature, different kiln, different firing rates, etc? It is so out of range in limit formulas I may not continue with it but was thinking of a sculptural piece.

The Assad Black I'm not planning to use on functional. I was looking for a nice semi-matte for sculpture that doesn't have manganese.

-

Permalink Reply by Norm Stuart on June 1, 2015 at 11:27am

-

In this particular instance I did apply the oxides mixed with flux to the unfired fairly wet clay.

I'll be interested to see what it looks like after a bisque, and again after high fire. I may end up later applying a layer of some sort of clear glaze over the surface.

When I no special ideas for a project I sometimes make something simple just to use as a test tile for exploring the boundaries of glazing, which is what I find more interesting.

I tore ~4mm thick, textured clay into strips and pieces and draped onto a bowl with a base then added on the bottom. Due to the thinness of each clay strip, I used Pat Horsley's "score-no-more" brushed onto the surface to attach each piece without scoring or applying pressure.

It's porous like a basket so I wanted to experiment with two primary colors, black interior and white exterior, which won't melt through the basket structure to affect the other color.

New things keep my interest. I've often said if I don't find at least three new things which don't work with experimental pieces like this, I didn't didn't try hard enough.

This idea started with "Tarp Weights" for a new tarp - tarps cover our raw materials stored on pallets.

Someone had used a fairly open (porous) clay for the weights, so after they were bisqued I dipped them in a solution of water mixed with two water soluble fluxes - lithium carbonate and potassium carbonate. After firing to Cone 6 they were completely densified with a surface just glassy enough that they'll stay clean.

If we apply glaze to the surface of these weights they quickly chip off pieces of sharp glass as the tarps are thrown open and the tarp-weight hits something hard.

-

Permalink Reply by Gina Skillings on June 1, 2015 at 1:34pm

-

I'd not heard of 'score-no-more' before. I've made and used paper clay for repairs and mixed up some of Lana Wilson's magic water hoping that some in class that don't score as well as they should would be helped a little with Lana's mix. I may try out some 'score-no-more' when there's lots of tiny little bits to add to a piece.

I hope you'll post a photo and update of your experiment.

Videos

Use These Links to Support Us

Low cost flat lapping disc can be used on you potters wheel if you, drill bat pin holes in it, and provide a trickle of water to cool it. At amazon.com, 120 grit for aggressive material removal. Click the image to purchase

Members have had great things to say about John Britt's new book, Mid-Range Glazes. Click the image to buy from Amazon.com

Purchase Glazes Cone 6 by Michael Bailey, The Potters Book of Glaze Recipes by Emmanuel Cooper, or Making Marks by Robin Hopper, all available at amazon.com. Mastering Cone 6 Glazes by John Hesselberth & Ron Roy is now out of print.

Harbor Freight is a great place to find unbeatable prices for better HVLP spray guns with stainless steel parts and serviceable economy models, as well as detail guns, all tested by our members for spraying glazes, as well as compressors to power the guns. As yet no one has tested and commented on the remarkably inexpensive air brushes at harbor freight.

The critter siphon gun is a spray alternative that is well liked by some of our members, and is available at amazon.

Amazon is also a competitive source for photo light tents for shooting professional quality pictures of your work. They also have the EZ Cube brand favored by several of our members. You might also want to purchase the book Photographing Arts, Crafts and Collectibles . . .

If you are up to creating videos of your work or techniques you might want to invest in a flip video camera

Following are a few scales useful for potters. Ohaus Triple Pro Mechanical Triple Beam Balance, 2610g x 0.1g, with Tare $169.00

And finally a low cost clone of the OHaus. The Adam Equipment TBB2610T Triple Beam Mechanical Balance With Tare Beam $99.62

ebay is a great alternative for many tools and the equipment used in the ceramics studio - kilns, wheels, extruders, slab rollers are often listed there both new and used.

Tips for Members

If you just want to spout off, it is best accomplished as a blog posting. If you want to get more guidance and ideas from other members, ask a question as a new discussion topic. In the upper right corner of the lists for both types of posting, you will find an "+Add " button. Clicking it will open an editor where you create your posting. 4/16/2014

© 2026 Created by Andrea Wolf.

Powered by

![]()