Electric Mid&Hi Fired Ceramics

Potters & Sculptors - Making Rock from Mud

-

Labeling Machine

- Female

- Vista, CA

- United States

- Share on Facebook MySpace Tweet

- Blog Posts

- Discussions

- Events

- Groups

- Photos

- Photo Albums

- Videos

RSS

Packaging Machinery Over-Specification in California: When Bigger Machines Reduce Stability

In California manufacturing, speed sells.

Brochures highlight maximum output. Sales sheets emphasize peak RPM. Equipment is often selected based on the highest number printed on the page.

But in many California plants, instability does not come from under-capacity.

It comes from over-specification.

Bigger packaging machinery does not automatically create stable production. In fact, oversized systems often reduce control margin and increase performance variability.

The California Context

California manufacturers operate under unique pressures:

- High labor costs

- Strict food and pharmaceutical compliance

- Frequent SKU changes

- Limited production floor space

- Energy efficiency requirements

In this environment, sustained throughput matters more than peak capability.

A packaging machine rated for 300 bottles per minute may look impressive. If the facility only needs 140, that excess capacity can introduce mechanical imbalance.

Where the Assumption Breaks

The common belief is simple:

“Buying the largest packaging machine protects future growth.”

This ignores operating range behavior.

Every piece of packaging machinery has a designed performance band. When equipment runs far below its intended operating zone, control precision can degrade.

Oversized components often create:

- Reduced mechanical rhythm

- Inconsistent torque behavior

- Narrower effective timing windows

- Accumulation imbalance

The result is subtle oscillation.

Capacity vs Operating Stability

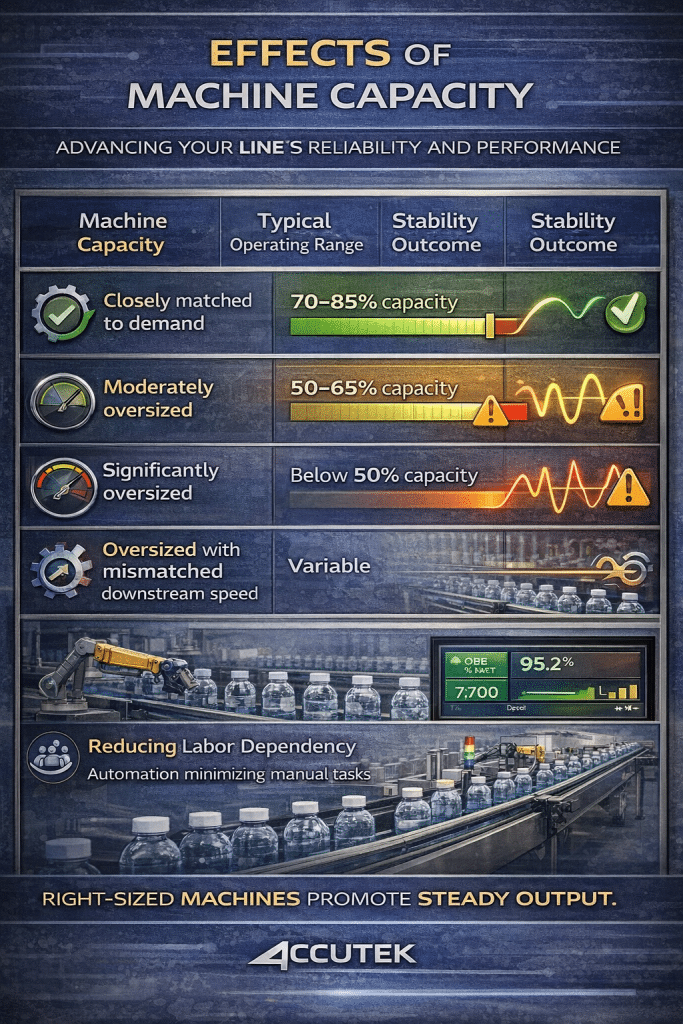

| Machine Capacity | Typical Operating Range | Stability Outcome |

|---|---|---|

| Closely matched to demand | 70–85% capacity | Stable rhythm |

| Moderately oversized | 50–65% capacity | Mild variability |

| Significantly oversized | Below 50% capacity | Oscillation risk |

| Oversized with mismatched downstream speed | Variable | Synchronization loss |

Equipment performs best when operating near its designed load band.

Running far below design range can reduce mechanical consistency.

The Hidden Risk of Partial Utilization

Oversized packaging machinery may require:

- Higher torque head inertia

- Larger drive assemblies

- Longer transfer distances

- Wider acceleration curves

When these systems operate at reduced speed, engagement timing can fluctuate.

For example, a high-speed rotary capper designed for aggressive torque engagement may produce inconsistent results when slowed significantly. The torque curve changes, which affects seal stability.

This does not show as a major fault.

It shows as performance drift.

Oversized Components and System Risk

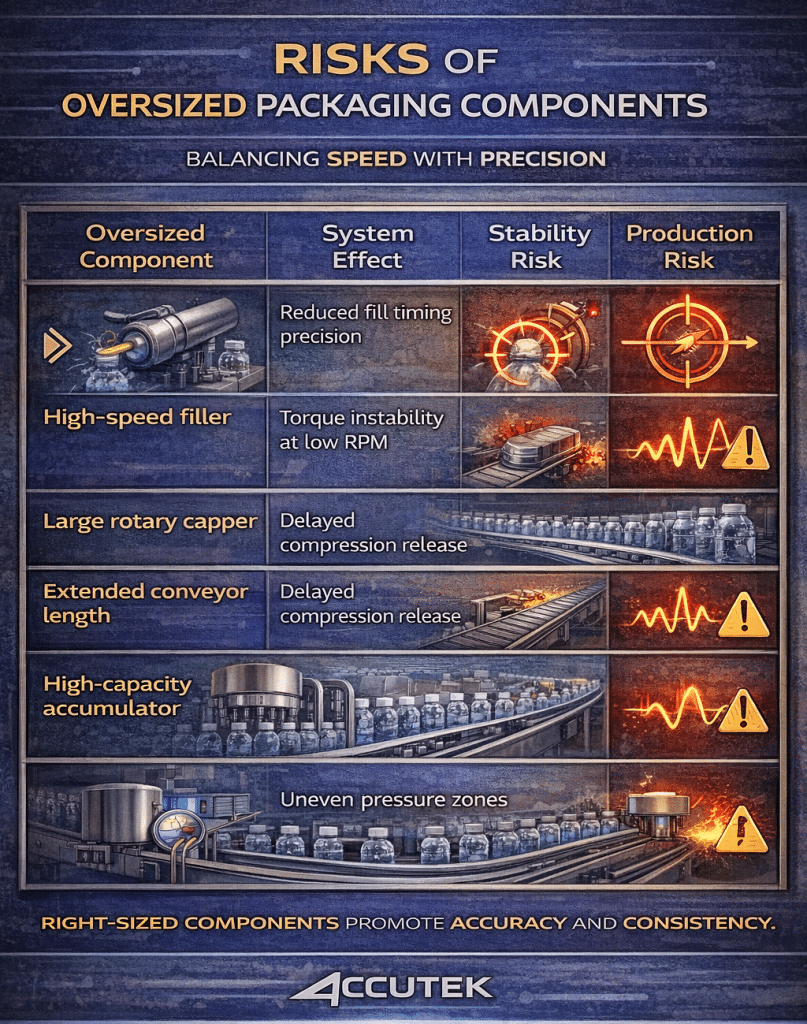

| Oversized Component | System Effect | Production Risk |

|---|---|---|

| High-speed filler | Reduced fill timing precision | Weight variation |

| Large rotary capper | Torque instability at low RPM | Seal inconsistency |

| Extended conveyor length | Delayed compression release | Flow oscillation |

| High-capacity accumulator | Uneven pressure zones | Restart shock |

Oversizing increases complexity without always improving output.

In California facilities where compliance matters, stability is often more valuable than raw speed.

Why California Facilities Feel This More

California manufacturers frequently handle:…

The post appeared first on Accutek Packaging Eqpt.: Filling, Capping, Labeling Machines.

Packaging Line Timing Windows: Designing for Tolerance Instead of Speed

Most packaging lines do not fail because they are too slow.

They fail because their timing windows become too narrow.

In many U.S. facilities, speed is treated as the primary solution. When output drops, operators increase RPM. When demand rises, management pushes acceleration.

But higher speed reduces tolerance.

When tolerance shrinks, instability grows.

What Is a Timing Window?

A timing window is the acceptable range in which one packaging machine transfers product to the next without disruption.

Every stage in packaging machinery operates inside a timing band:

- Conveyor transfers

- Filling index cycles

- Cap engagement points

- Label placement alignment

- Buffer release intervals

As long as spacing and synchronization remain inside that band, the system stays stable.

When variation exceeds it, errors begin.

Where the Assumption Breaks

The common belief is simple:

“If a packaging machine is rated for 140 bottles per minute, the line should run at 140.”

This ignores tolerance stacking across packaging machinery.

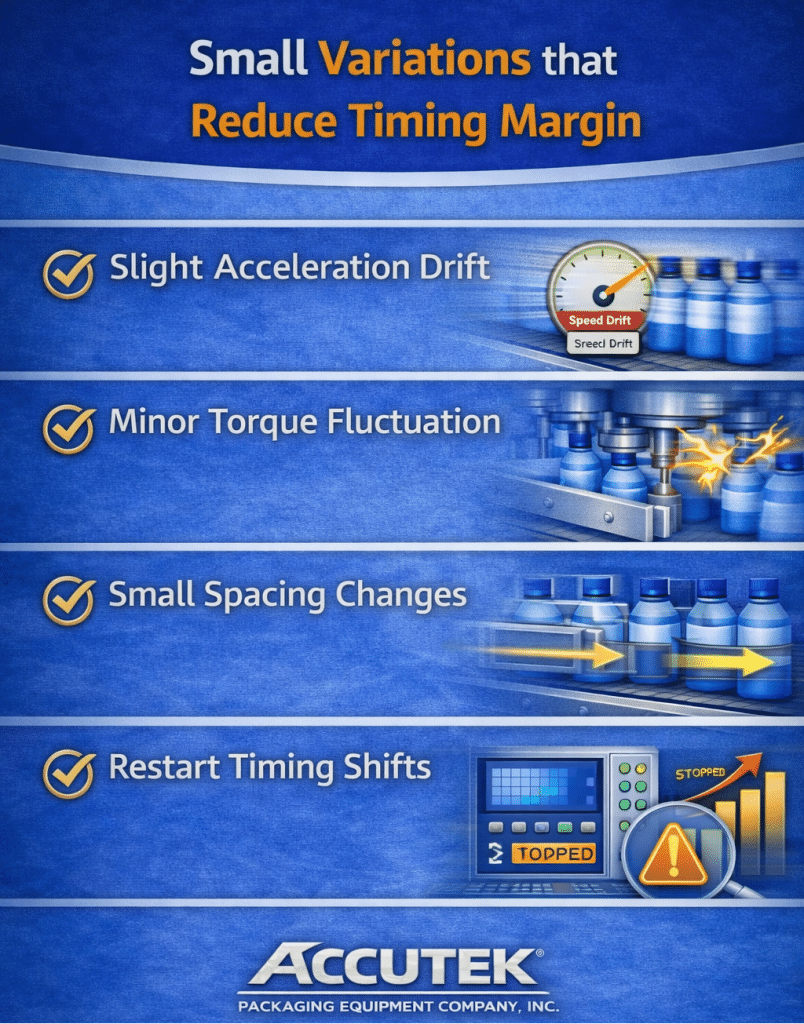

Each stage introduces small variation:

- Slight acceleration drift

- Minor torque fluctuation

- Small spacing changes

- Restart timing shifts

Individually, these variations seem minor.

Together, they compress the system’s timing window.

Machine Stage and Timing Tolerance

| Line Stage | Typical Timing Window | Risk When Margin Shrinks |

|---|---|---|

| Conveyor transfer | Spacing tolerance band | Container compression |

| Filling cycle | Index timing range | Fill variance |

| Capping engagement | Torque timing band | Reject increase |

| Label application | Alignment window | Cosmetic defects |

Each packaging machine depends on the previous one staying inside tolerance.

When one stage drifts, the next absorbs the error.

As speed increases, that margin narrows.

Speed and Window Compression

Higher speed reduces the time available for correction.

At elevated RPM:

- Containers arrive closer together

- Sensors react faster

- Mechanical engagement windows shorten

- Buffer absorption time decreases

This does not increase stability.

It reduces forgiveness.

Speed Increase and System Effect

| Speed Change | Window Effect | System Result |

|---|---|---|

| Moderate increase | Slight margin reduction | Manageable variation |

| Aggressive acceleration | Significant window shrink | Compression shock |

| High RPM with variability | Minimal tolerance band | Frequent micro-stops |

| Coordinated speed profile | Preserved margin | Sustained throughput |

When packaging machinery operates at high speed without coordination, small disturbances expand quickly.

Designing for Tolerance Instead of Maximum RPM

Throughput stability depends on preserving timing margin across packaging machinery.

Engineering for tolerance requires:

- Matched acceleration curves

- Coordinated restart logic

- Controlled buffer release

- Stabilized torque ramp engagement

Accutek Packaging Equipment designs integrated systems so each packaging machine follows a synchronized speed profile. When packaging machinery is engineered as a unified …

The post appeared first on Accutek Packaging Eqpt.: Filling, Capping, Labeling Machines.

Labeling Machine's Page

Profile Information

- What is your experience with ceramics in general. (Long answer encouraged)

- nothing, just want to visit this site to learn

- What is your current involvement with electric fired ceramics? (long answer encouraged)

- nothing, just want to visit this site to learn

- All our content is viewable by the public. Why do you want to be a member, when you can already see everything as a non-member?

- yes

- Where do you work on your ceramics projects?

- other

- How did you find this network?

- referred by friend

Videos

Use These Links to Support Us

Low cost flat lapping disc can be used on you potters wheel if you, drill bat pin holes in it, and provide a trickle of water to cool it. At amazon.com, 120 grit for aggressive material removal. Click the image to purchase

Members have had great things to say about John Britt's new book, Mid-Range Glazes. Click the image to buy from Amazon.com

Purchase Glazes Cone 6 by Michael Bailey, The Potters Book of Glaze Recipes by Emmanuel Cooper, or Making Marks by Robin Hopper, all available at amazon.com. Mastering Cone 6 Glazes by John Hesselberth & Ron Roy is now out of print.

Harbor Freight is a great place to find unbeatable prices for better HVLP spray guns with stainless steel parts and serviceable economy models, as well as detail guns, all tested by our members for spraying glazes, as well as compressors to power the guns. As yet no one has tested and commented on the remarkably inexpensive air brushes at harbor freight.

The critter siphon gun is a spray alternative that is well liked by some of our members, and is available at amazon.

Amazon is also a competitive source for photo light tents for shooting professional quality pictures of your work. They also have the EZ Cube brand favored by several of our members. You might also want to purchase the book Photographing Arts, Crafts and Collectibles . . .

If you are up to creating videos of your work or techniques you might want to invest in a flip video camera

Following are a few scales useful for potters. Ohaus Triple Pro Mechanical Triple Beam Balance, 2610g x 0.1g, with Tare $169.00

And finally a low cost clone of the OHaus. The Adam Equipment TBB2610T Triple Beam Mechanical Balance With Tare Beam $99.62

ebay is a great alternative for many tools and the equipment used in the ceramics studio - kilns, wheels, extruders, slab rollers are often listed there both new and used.

Tips for Members

If you just want to spout off, it is best accomplished as a blog posting. If you want to get more guidance and ideas from other members, ask a question as a new discussion topic. In the upper right corner of the lists for both types of posting, you will find an "+Add " button. Clicking it will open an editor where you create your posting. 4/16/2014

© 2026 Created by Andrea Wolf.

Powered by

![]()

Comment Wall (1 comment)

You need to be a member of Electric Mid&Hi Fired Ceramics to add comments!

Join Electric Mid&Hi Fired Ceramics

I picked interest on you after going through your short profile and demand it necessary to write you immediately. I have something very vital to disclose to you, but I found it difficult to express myself here, since it's a public site.Could you please get back to me on jonathanbewes9@gmail.com for the full details

Best Regards

Jonathan Bewes